Insider Brief

- Chef Robotics and JBT Marel’s Proseal formed a partnership to deliver an integrated automation solution that assembles and tray-seals fresh and frozen RTE/RTC meals for high-mix food manufacturing lines.

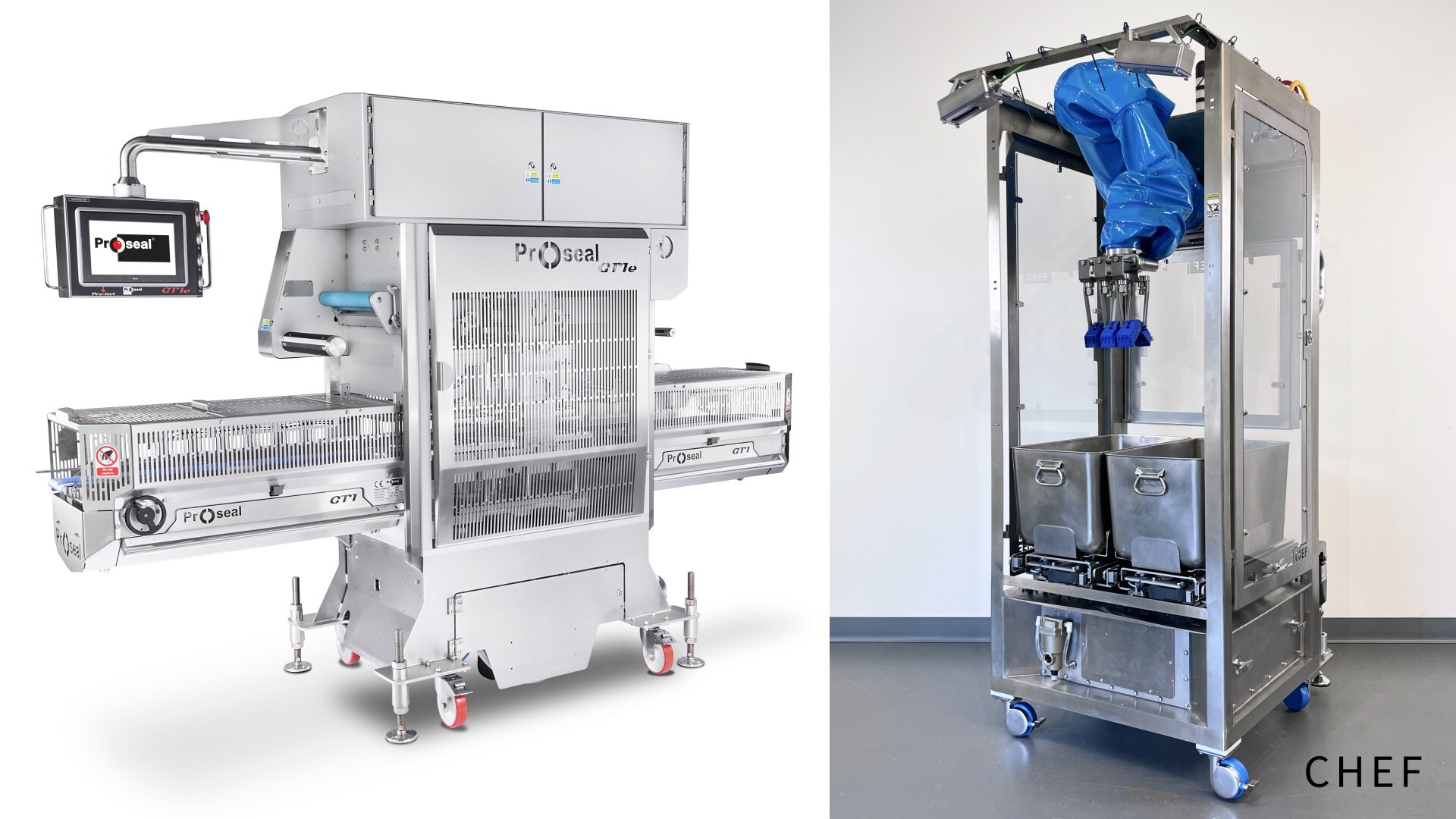

- Chef supplies AI-enabled robots with vision to pick and place varied ingredients into conveyor-fed trays in a worker-footprint and human-safe configuration, while Proseal provides rapid-changeover tray sealing to extend automation through packaging.

- The joint solution is available today in the U.S. and Canada, with demonstrations slated for PACK EXPO Las Vegas 2025 (booths SU-35058 and N-8612).

PRESS RELEASE – Chef Robotics, a leader in AI-enabled robotic meal assembly for the food manufacturing industry, and JBT Marel’s Proseal, a global leader in tray sealing solutions, are partnering to provide a joint solution for meal assembly automation. The solution will allow food manufacturers to flexibly automate the assembly and packaging of fresh and frozen ready-to-eat (RTE) and ready-to-cook (RTC) meals.

Food manufacturers have traditionally found meal assembly challenging to automate, especially in high-mix production environments that require different stock-keeping units (SKUs) on the same production line with quick changeovers. Chef is addressing this challenge with flexible robots that occupy the same footprint as a worker and operate safely alongside humans while picking and placing various ingredients into trays on a conveyor. Utilizing an AI-enabled perception system, Chef robots accurately detect trays and precisely place ingredients while meeting high throughput requirements.

“Food companies are under more pressure than ever to reduce costs and increase throughput while maintaining flexibility,” said Rajat Bhageria, CEO of Chef Robotics. “By partnering with Proseal, we can deliver a seamless automation solution that goes beyond meal assembly to include sealing and packaging. Food manufacturers with high-mix, high-volume production environments can now handle food assembly and packaging with the same precision and flexibility at a fraction of the labor cost.”

The joint solution combines Chef’s AI focus and flexibility with Proseal’s robust, high-quality tray sealing machines and packaging solutions to provide food manufacturers with a flexible end-to-end solution for their meal assembly and packaging needs. Chef’s robots and Proseal’s tray sealing machines are easy to use and support rapid changeovers, freeing up line workers’ time for more meaningful tasks.

“Chef brings a next-generation approach to food automation with its AI and vision-based robotics platform,” said Chris Mills, Director of Engineering at Proseal. “Speed and flexibility are two important differentiators for Proseal as well as Chef, so I instantly knew we would want to create a partnership. Together, we can help our customers automate more production lines while remaining agile in the ever-changing food manufacturing market.”

Chef and Proseal’s joint solution will be available to food manufacturers in the US and Canada starting today. Contact Chef or Proseal to learn more, and visit us at PACK EXPO Las Vegas 2025 at booths SU-35058 and N-8612 next week.

(Photo Credit: Chef Robotics)