Insider Brief

- AI-driven multi-agent systems integrated with manufacturing execution systems can enable adaptive, decentralized decision-making in factories, marking a critical step toward Industry 4.0 and Industry 5.0.

- These systems use machine learning, reinforcement learning, and digital twins to improve scheduling, predictive maintenance, and real-time resource allocation.

- Adoption remains limited by scalability, interoperability, cybersecurity, and readiness-level barriers, requiring industry–academia collaboration and workforce upskilling for large-scale deployment.

- Photo by Christopher Burns

Artificial intelligence is reshaping manufacturing, but real-world adoption lags behind the promise. A new research survey published in Operations Research Forum reviews how AI-driven multi-agent systems can make factories smarter while highlighting the obstacles that keep most projects stuck in prototypes rather than production.

Factories have integrated digital tools for decades, but Industry 4.0 — the shift to data-driven, cyber-physical production — demands more than just automation. The new study, led by Arti Bandhana and Jiří Vokřínek at the Czech Technical University, finds that while manufacturers see value in AI, practical deployment remains limited.

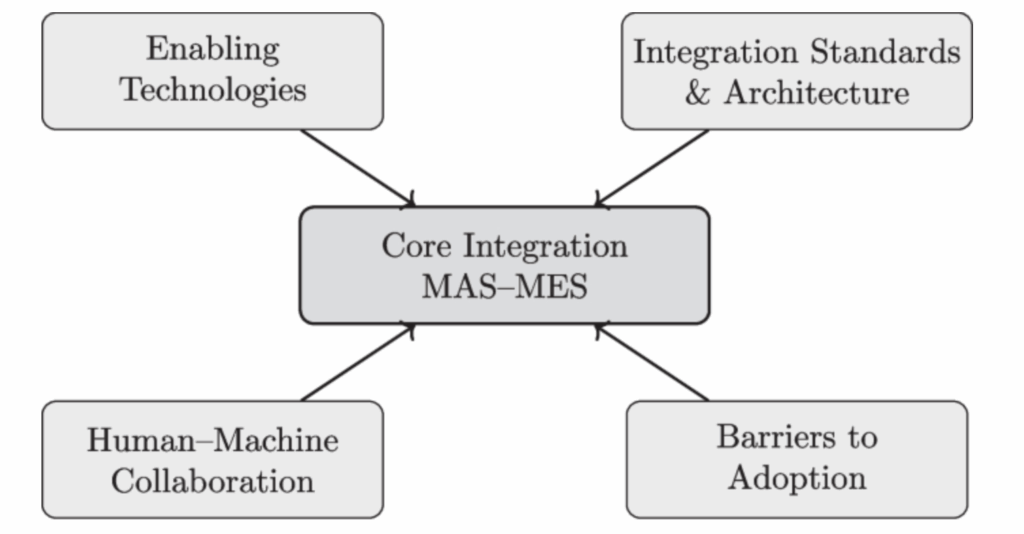

The research centers on how multi-agent systems (MAS) — groups of autonomous software agents that make decisions together — can integrate with manufacturing execution systems (MES), which manage day-to-day factory operations. The team argues that this pairing, powered by AI, could enable decentralized decision-making, predictive maintenance and adaptive production schedules. Yet despite a surge of academic activity, industrial adoption remains rare.

The researchers note that the gap between laboratory demonstrations and factory-floor implementation resembles earlier waves of industrial change. Like past revolutions in steam, electricity and automation, today’s transition faces fears of job loss, concerns over security and a lack of shared technical standards.

The survey positions MAS–MES integration as the anchor of future manufacturing and organizes findings across four themes: enabling technologies, integration standards and architecture, human–machine collaboration, and barriers to adoptionAIManufacturing.

Key findings include:

- AI enhances MAS capabilities. Techniques such as machine learning, reinforcement learning, natural language processing, and generative AI help agents learn from data, communicate in natural language, and adapt to changing environments.

- Digital twins bridge the gap. Virtual replicas of machines and production lines allow simulations before deployment, reducing risk and accelerating scaling.

- Barriers remain systemic. Even with advanced algorithms, manufacturers struggle with scalability, interoperability across systems, integration with legacy infrastructure and cybersecurity risks.

- Readiness levels are low. Most MAS–MES projects remain at Technology Readiness Level (TRL) 4–6 and Manufacturing Readiness Level (MRL) 5–8, indicating lab prototypes or pilot projects rather than full deployments.

- Human–machine collaboration defines Industry 5.0. Beyond efficiency, the next phase of industrial development emphasizes sustainability and cooperation between humans and AI.

The paper stresses that progress requires not just technological advances but also workforce training, better standards, and stronger collaboration between academia and industry.

Why Multi-Agent Systems Matter

Traditional factory control systems rely on centralized decision-making. MAS change that approach. Each agent — software acting on behalf of a process, robot, or machine — can operate independently but coordinate with others. The structure resembles a team where members divide tasks, adapt to changes, and collaborate to meet shared goals.

When connected to MES, MAS agents could reschedule production in real time if a machine fails, allocate resources to priority orders, or predict maintenance needs before breakdowns occur. AI methods like reinforcement learning allow agents to improve with experience, while generative AI and natural language models make human interaction more intuitive.

According to the study, this decentralized model promises agility and resilience but remains difficult to scale. Many MAS frameworks developed in academia, such as JADE or ZEUS, were not designed with modern AI or industrial standards in mind. As a result, most projects fail to move beyond simulation environments.

Lessons From Past Revolutions

The researchers place today’s challenges in historical context. Every industrial revolution has carried both disruption and opportunity. Steam engines triggered fears of mass unemployment. Electricity and assembly lines brought labor conflicts. Automation raised questions about privacy and safety.

Industry 4.0 continues the pattern. AI and robotics spark anxiety about job displacement.

“Historically, the fear of job displacement has persisted in every industrial revolution; each wave of technological revolutions brings the fear of humans losing jobs to machines,” the researchers write. “Recent discussions have focused on AI and robotics potentially automating “lower-tier” and service-level jobs.”

The study argues that history suggests a more nuanced outcome: automation eliminates repetitive roles but also creates new jobs requiring creativity, emotional intelligence, and problem-solving. This aligns with what some economists call the “Feeling Economy,” where uniquely human skills gain value as machines take over routine tasks.

The paper also emphasizes that privacy and security concerns have escalated across multiple revolutions. Data-driven systems introduce risks of breaches and manipulation. Building trust will require transparent governance, evolving regulatory frameworks, and ethical AI practices.

Case Studies and Early Applications

The study highlights several MAS implementations tested in controlled environments:

- A job shop manufacturing case where MAS improved flexibility and reduced setup times.

- A production cell for metal plate forging that used MAS to autonomously control workflows.

- Scheduling systems that handled rework rates in custom manufacturing environments.

While results were promising, all remained confined to simulations or small pilots. High upfront costs, integration difficulties with legacy MES, and unclear return on investment limited broader rollout. Industry stakeholders often found incremental improvements with traditional automation more practical than wholesale adoption of MAS systems.

Unlike a single experiment, this paper is a survey study — it synthesizes findings from academic databases, industry reports and historical analysis. The researchers also introduced an unusual method by testing whether large language models, such as ChatGPT and Microsoft Copilot could generate insights aligned with their literature review.

The AI outputs echoed many of the paper’s themes, such as interoperability, predictive maintenance and the importance of human–machine synergy. While the authors caution against over-reliance on AI-generated material, they argue that this approach shows how machine assistance can support research synthesis in the future.

Limitations: Theoretical and Simulation-Based

The study acknowledges several limitations. For example, most MAS–MES research remains theoretical or simulation-based, meaning conclusions about real-world effectiveness are tentative. Readiness levels remain too low for widespread industrial deployment. The literature is also saturated with surveys, leading to repetition rather than new applied insights.

Another limitation is the scarcity of industrial data available to researchers. Without access to real production environments, most studies cannot validate scalability, cost-effectiveness, or long-term resilience. This gap leaves many unanswered questions about ROI, integration with diverse factory systems, and organizational adoption.

Finally, the AI-assisted research component remains exploratory. Large language models can generate relevant themes but also risk bias, factual errors, or repetition. Human oversight and critical evaluation remain essential.

The Road Ahead

The study calls for a problem-driven approach. Instead of chasing technology for its own sake, researchers and manufacturers should focus on well-defined challenges — such as reducing downtime in specific production lines or optimizing energy use in a particular industry. High-TRL pilot projects that demonstrate measurable ROI will be essential to shift MAS adoption beyond laboratories.

Key priorities for future research include:

- Interoperability standards. Frameworks like OPC UA, RAMI 4.0, and Unified Namespace can provide shared structures for cross-system communication.

- Cybersecurity and privacy. As systems become more connected, protecting against breaches and adversarial attacks must be built into MAS architectures.

- Human–machine collaboration. Industry 5.0 envisions humans and AI working together. Natural language interfaces, generative AI, and digital twins can make interactions more intuitive.

- Workforce upskilling. Training workers in AI, MAS, and data-driven decision-making will be critical to ensure adoption.

- Industry–academia collaboration. Field trials, real-world datasets, and testbeds are necessary to validate concepts and push MAS–MES systems up the readiness ladder.

The path ahead toward AI-guided smart manufacturing can also be paved by training right now, according to a report from the Bank of Montreal.

The company recommends that, in addition to receiving buy-in from key decision-makers, companies should also:

- Invest in regular AI training. Since AI is evolving so rapidly, this is not a one-and-done upskilling.

- Prioritize building a responsible AI program. Employees want reassurance their leaders are taking an ethical approach to AI.

- Create spaces for responsible experimentation. The more regularly employees use AI, the more clearly they’ll see the benefits, limitations, and risks.

Why It Matters

The future of manufacturing will not be defined by machines replacing humans, but by humans and machines working together. Industry 4.0 and the emerging Industry 5.0 demand that balance. According to the study, only by bridging theory and practice can manufacturers capture the full promise of AI-driven production

The gap between theory and practice in manufacturing mirrors broader challenges in AI. While algorithms show promise in labs, real-world conditions are complex, unpredictable, and shaped by legacy systems. Bridging this gap is not just about efficiency. Smarter factories could strengthen supply chains, reduce waste, and support sustainable industrial growth.

As the study emphasizes, progress requires more than technical breakthroughs. It demands standards, trust, skilled workers, and clear problem definitions. It also requires collaborations across fields, disciplines and industries.

“Advancing AI-driven MAS-MES integration requires close collaboration among researchers, manufacturers, technology providers, and policymakers,” the team writes. “Future research must prioritize bridging the gap between theoretical advancements and practical feasibility by addressing industry-specific needs and well-defined objectives. This requires cross-disciplinary collaboration to accelerate industrial adoption. Without these efforts, technologies will remain confined to theoretical exploration, delaying their transition into production-ready systems.”