Insider Brief

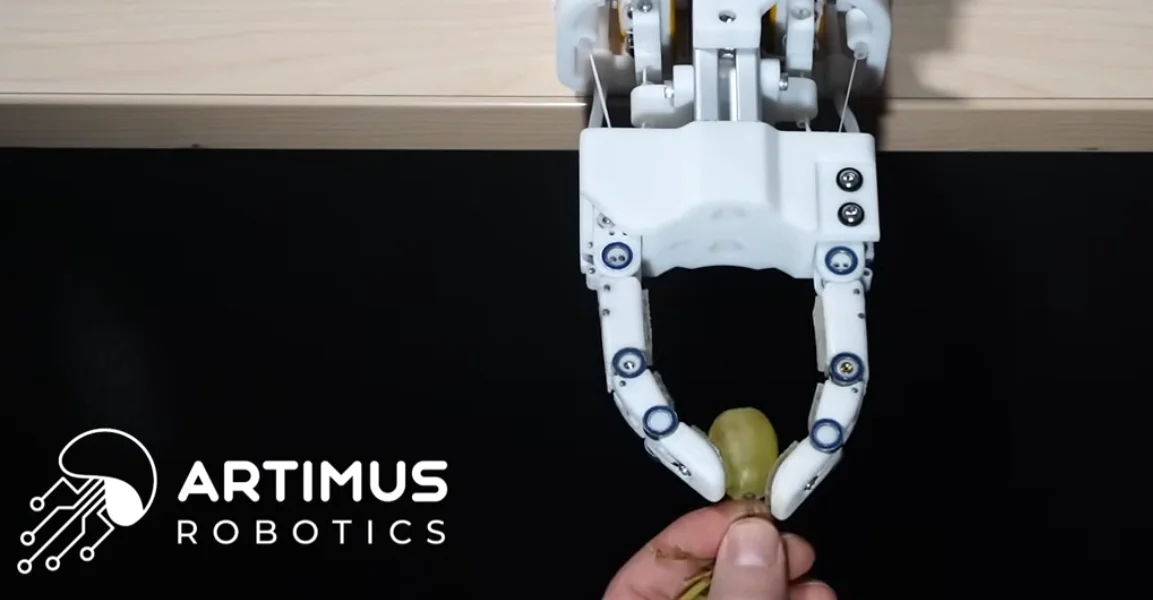

- Artimus Robotics has introduced a new generation of its HASEL artificial muscles that more than double the mechanical output of the prior version and is seeking select partners to test and integrate the technology into robotic manipulators.

- The upgraded actuators incorporate materials and manufacturing improvements and are now fully encapsulated to enhance safety and simplify integration into humanoid and industrial automation systems.

- The electrohydraulic HASEL design, developed as a spinout from the University of Colorado Boulder, uses lightweight films, fluid and flexible conductors to enable compact, high-degree-of-freedom robotic motion intended to more closely replicate mammalian skeletal muscle performance.

Artimus Robotics has unveiled a new version of its artificial muscles, saying the upgraded actuators deliver more than twice the mechanical output of the previous generation and are now ready for broader real-world testing. The company said it is seeking select partners to evaluate and integrate the technology into robotic manipulators across applications ranging from humanoids to industrial automation.

According to Artimus, the gains come from advances in materials science and manufacturing, along with full encapsulation of the actuators to improve safety and simplify system integration. The improvements move its artificial muscles closer to replicating the performance of mammalian skeletal muscle, particularly in compact systems requiring high degrees of freedom.

“Recreating the remarkable dexterity of the human hand requires actuators that can react quickly & interact safely with the physical environment. With this new generation of actuators, we’re able to offer customers a product that is easier to use & integrate into their systems.” Eric Acome, PhD, CEO of Artimus Robotics, said in the announcement.

The company’s Hydraulically Amplified Self-Healing Electrostatic, or HASEL, actuators use an electrohydraulic mechanism built from lightweight films, fluid and flexible conductors rather than traditional rigid electromagnetic motors. Artimus, a spinout from the University of Colorado Boulder, is positioning the technology for dexterous robotic hands and other systems that require fast, responsive and safer physical interaction.

Image credit: Artimus Robotics