Insider Brief

- PLP and FulcrumAir have entered a multi-year strategic partnership to co-develop robotic installation systems aimed at automating overhead power line construction, according to the companies.

- The collaboration builds on earlier joint deployments of FulcrumAir’s LineSpider and LineFly robots to install PLP hardware, with the expanded effort focused on improving installation speed, precision and worker safety while reducing exposure to hazardous environments.

- The companies said utilities are increasingly adopting automation to address grid expansion and modernization demands, positioning the partnership to support broader deployment of robotics in power line construction and maintenance.

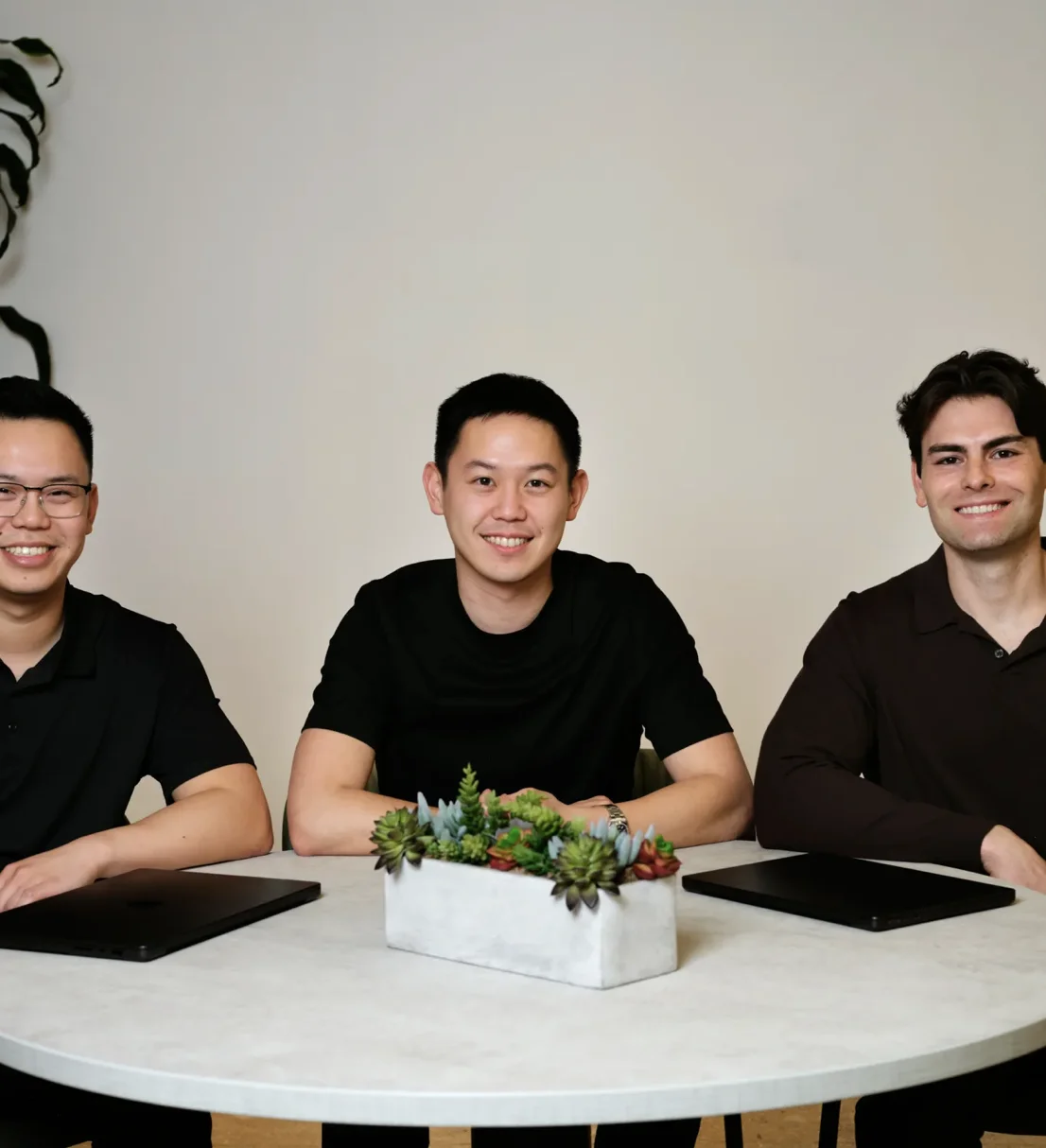

PRESS RELEASE — PLP, a global leader in engineered solutions for energy, communications, and other critical infrastructure, and FulcrumAir, a pioneer in robotic technologies for the electric power industry, announced a new multi-year strategic partnership to co-develop next-generation robotic installation systems. These advanced solutions are designed to transform overhead power line construction—delivering unparalleled efficiency, enhanced safety, and superior reliability for utilities worldwide.

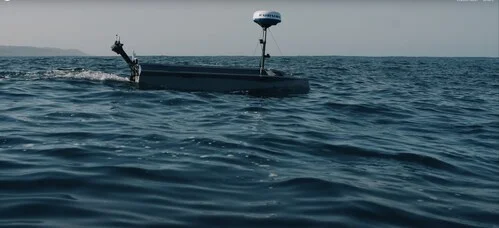

Building on a series of successful innovations jointly developed by the two companies—including the LineSpider™ robot for installing PLP CUSHION-GRIP® Twin Spacers and the LineFly™ family of robotic systems for deploying both CUSHION-GRIP Twin Spacers and PLP BIRD-FLIGHT™ Diverters—this expanded collaboration underscores their shared commitment to accelerating technology development and shaping the future of utility infrastructure.

“For nearly 80 years, PLP has been at the forefront of product and process innovation for the electric power industry. This expanded partnership with FulcrumAir reinforces our long-standing commitment to providing utilities with the world’s most advanced solutions built to the highest quality standards,” said Ryan Ruhlman, President of PLP. “By integrating robotics into installation processes and reimagining product design for automated deployment, we aim to enhance safety and efficiency across the industry while also creating new opportunities for PLP’s strategic growth and market leadership.”

Together, PLP and FulcrumAir will focus on developing robotic systems designed to:

- Increase installation efficiency and reduce project timelines

- Improve safety by reducing lineworker exposure to hazardous environments

- Deliver greater precision and consistency in hardware placement and quality control

- Enable new revenue opportunities and reinforce both companies’ leadership positions

“Robotics is redefining what’s achievable in power line construction, and our collaboration with PLP accelerates that transformation,” said Patrick Arnell, President & CEO of FulcrumAir. “Elevating worker safety, expanding workforce capabilities, and enabling utilities to adapt faster—that is how we build a more resilient, efficient grid of the future.”

As utilities increasingly turn to automation to meet rising infrastructure demands, the PLP–FulcrumAir partnership positions both companies at the forefront of this shift. With new systems already in development, the collaboration will help lead the next decade of grid expansion, infrastructure modernization, and technological innovation.

ABOUT PLP

PLP protects the world’s most critical connections by creating stronger and more reliable networks. The company’s precision-engineered solutions are trusted by energy and communications providers worldwide to perform better and last longer. With locations in over 20 countries, PLP works as a united global corporation, delivering high-quality products and unparalleled service to customers around the world.

ABOUT FULCRUMAIR

FulcrumAir’s purpose-built robotic tools are redefining the power line industry by improving safety, accelerating project execution, and enhancing workforce efficiency. Backed by extensive engineering and field development, FulcrumAir delivers scalable robotics for complex line construction and maintenance–driving the future of reliable power delivery.

Image credit: PLP