Insider Brief

- HII signed a memorandum of understanding with Path Robotics to explore integrating Path’s AI-driven autonomous welding systems into shipbuilding operations, according to HII.

- The companies will evaluate collaboration across autonomous shipbuilding capability development, workforce training to extend automation, and creation of an intellectual property framework for AI-based welding, while also pursuing R&D to integrate Path’s technology with systems including HII’s ROMULUS unmanned surface vehicles.

- Path’s Obsidian AI welding model and vision system are designed to enable robotic arms to adapt in real time to complex shipyard conditions, as HII seeks to increase shipbuilding throughput beyond a reported 14% gain in 2025 and target a further 15% increase in 2026.

PRESS RELEASE — HII (NYSE: HII) and Path Robotics signed a memorandum of understanding (MOU) to explore the integration of Path’s physical artificial intelligence (AI) for welding into shipbuilding operations that could accelerate throughput, strengthen the maritime industrial base, and augment the shipbuilding workforce. The MOU signing ceremony took place at Path Robotics’ headquarters and was attended by Eric Chewning, HII’s executive vice president of maritime systems and corporate strategy, and Andy Lonsberry, Path Robotics CEO and co-founder.

“We are excited to partner with Path Robotics to incorporate their state-of-the-art physical AI models to further augment our workforce and speed up U.S. Navy manned and unmanned shipbuilding production,” Chewning said. “Our shipbuilding throughput was up 14% in 2025 and we are looking for an additional 15% increase in 2026. By working with new partners like Path Robotics, we can further accelerate shipbuilding production. I look forward to jointly developing an autonomous AI-based welding solution that can help us meet Navy standards and be scaled in our shipyard facilities. Navigating this transformational partnership has the potential to increase our throughput efficiency without sacrificing quality.”

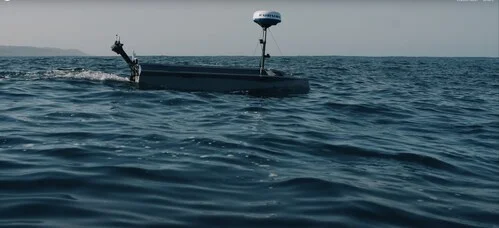

HII and Path Robotics will work to identify and potentially pursue future opportunities in three areas that include autonomous shipbuilding capability development, train a workforce to extend automation and establish an intellectual property framework for physical AI-based autonomous welding systems. In addition, the companies will pursue research and development around integrating Path’s physical AI models with other innovative shipbuilding technologies used in the construction of HII ships, to include HII’s ROMULUS line of unmanned surface vehicles. Together these technologies would augment the welding workforce, automate structural production, and accelerate throughput to advance national security objectives.

“Partnering with the nation’s largest military shipbuilder during such a critical time for national defense and manufacturing underscores the importance of what we’re building at Path,” Lonsberry said. “Welding is one of the hardest processes to automate in any industry, and shipbuilding is no exception. Path’s physical AI is purpose-built for that challenge – seeing, understanding, and adapting to real world conditions in real time. We’re honored to work alongside HII to help modernize defense manufacturing and strengthen the naval industrial base for decades to come.”

Prior to the MOU signing ceremony, attendees from HII, local dignitaries and Path stakeholders walked the Path Robotics factory floor and observed robotic welding demonstrations in the company’s new intelligence center. The demonstrations showcased how Path Robotics systems may be applicable to naval fabrication work, ranging from heavy foundations to large, complex ship structural assemblies. The technology showed how an autonomous welding system can adapt to unpredictable shipyard conditions, such as fit variations, complex joint types and different materials

Path’s physical AI model for welding, Obsidian™, and proprietary sensing and vision system transforms a traditional industrial robot arm from a rigid, repeat-only machine into a real-time perception and decision-making system that can see, understand, and adapt to the variations of a shipbuilding environment.

Currently, HII shipbuilders perform specialized, high-tolerance welding and direct weld support activities on large, complex ship structures without an AI-based autonomous welding capability. HII divisions use automated robot welders that require human collaboration — they are traditional panel line units, cobot welders that work alongside shipbuilders, or mechanized welders that follow pre-programmed paths. AI-driven autonomous welding technology presents a promising potential opportunity to expand distributed shipbuilding capacity and augment HII’s skilled workforce to accelerate delivery and meet the U.S. Navy’s growing demand.

Image credit: HII