Insider Brief

- A new Rice University study demonstrates AI-guided control of a soft robot arm powered entirely by light, without wires or onboard electronics.

- The system uses a neural network to determine laser light patterns that activate specific regions of a polymer-based arm, allowing it to perform complex motions like grasping or obstacle navigation.

- Researchers say the AI model learned efficient movement strategies from a small dataset, potentially enabling faster development of soft robotic tools for surgery, manufacturing, or other delicate, remote applications.

A new study from Rice University used artificial intelligence to precisely control a soft robot with no wires or onboard electronics, opening new possibilities for delicate, remote tasks in medicine and manufacturing.

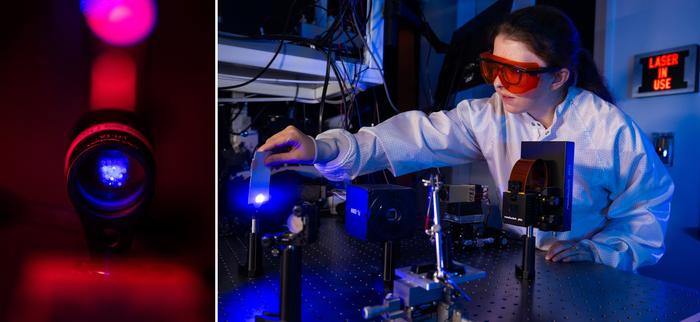

In research published in Advanced Intelligent Systems, Rice scientists combined smart materials, machine learning, and light-based control to guide a robotic arm built from a light-responsive polymer. Instead of relying on motors or cables, the azobenzene liquid crystalarm is powered and controlled by blue laser light that trigger localized bending of the material, which then relaxes when the light turns off, according to Rice.

“When we shine a laser on one side of the material, the shrinking causes the material to bend in that direction,” noted Elizabeth Blackert, a Rice doctoral alumna who is the first author on the study. “Our material bends toward laser light like a flower stem does toward sunlight.”

The key lies in how the AI model determines the exact light pattern needed to make the robot move as wanted.

A spatial light modulator splits a single laser into many small beams, called beamlets, with each able to target a specific area of the arm. The AI model calculates which segments to activate and with what intensity, enabling near-continuous motion similar to an octopus tentacle.

The team trained a convolutional neural network to predict the correct arrangement of laser beamlets to achieve a desired movement. By recording how the arm bent under different beam patterns, the AI learned how to reverse-engineer the necessary inputs for tasks like reaching around obstacles or striking a target. Once trained, the system could quickly and precisely generate complex motions with only a few external inputs, researchers noted.

Unlike conventional robots, soft robots can bend and flex in many directions, making them ideal for environments where rigid joints are impractical or unsafe.

“Building remotely and arbitrarily programmable soft robots requires a unique blend of expertise involving materials development, optical system design and machine learning capabilities. Our research team was uniquely suited to take on this interdisciplinary work,” pointed out Hanyu Zhu, Rice assistant professor of materials science and nanoengineering, who led the research team.

Current limitations include the arm’s two-dimensional motion, but future versions may use depth cameras or embedded sensors for 3D control. The researchers also note that the AI model needs only a small dataset to learn effective control strategies, which could speed development for new use cases.

Researchers said the system could eventually guide implantable medical devices, automate tasks with fragile materials, or operate in hazardous locations where electronics fail. The study was supported by the National Science Foundation, the Welch Foundation, and JPMorgan Chase AI Research.