Insider Brief

- R3 Robotics raised €20 million to scale automated disassembly of electric vehicle systems, aiming to industrialize the dismantling of batteries, e-drives, and power electronics as EV end-of-life volumes rise.

- The financing includes a €14 million Series A co-led by HG Ventures and Suma Capital, plus €6 million in European grants, and coincides with the company’s rebrand from Circu Li-ion and an expanded focus on full vehicle systems rather than batteries alone.

- The Luxembourg company’s AI- and robotics-driven platform targets a key bottleneck in EV recycling—safe, scalable dismantling of high-voltage systems—and will be deployed with partners such as Fortum Battery Recycling as R3 expands capacity in Germany and France and prepares for U.S. market entry in 2026.

R3 Robotics has raised €20 million to scale automated disassembly of electric vehicle systems.

The financing includes a €14 million Series A co-led by HG Ventures and Suma Capital, alongside €6 million in European grants, according to HG Ventures. The round coincides with the company’s rebrand from Circu Li-ion to R3 Robotics and a broadening of scope beyond battery packs to full electric drivetrains, power electronics and other high-value EV components. The new name reflects the company’s focus on repair, reuse, and recycling through industrial automation.

As EV adoption accelerates, end-of-life volumes of complex, high-voltage systems are expected to rise sharply. Today, most dismantling remains manual, costly and difficult to scale safely. Luxembourg-based R3 Robotics is positioning its automated platform as an upstream solution, turning dismantling into a repeatable, high-throughput industrial process rather than a labor-intensive one-off task, HG noted.

That approach aligns with tightening European regulation. The EU’s Battery Regulation and Critical Raw Materials Act are pushing recyclers and manufacturers to improve recovery rates, traceability and domestic sourcing of strategic materials, R3 Robotics said.

“The bottleneck isn’t recycling technology; it’s clean feedstock, meaning getting complex electrified systems safely and cost-effectively dismantled at an industrial scale,” CEO and co founder of R3 Robotics Antoine Welter said in the announcement. “We’re building a dismantling platform that turns end-of-life systems into a strategic source of critical materials and reusable components for advanced industrial economies.”

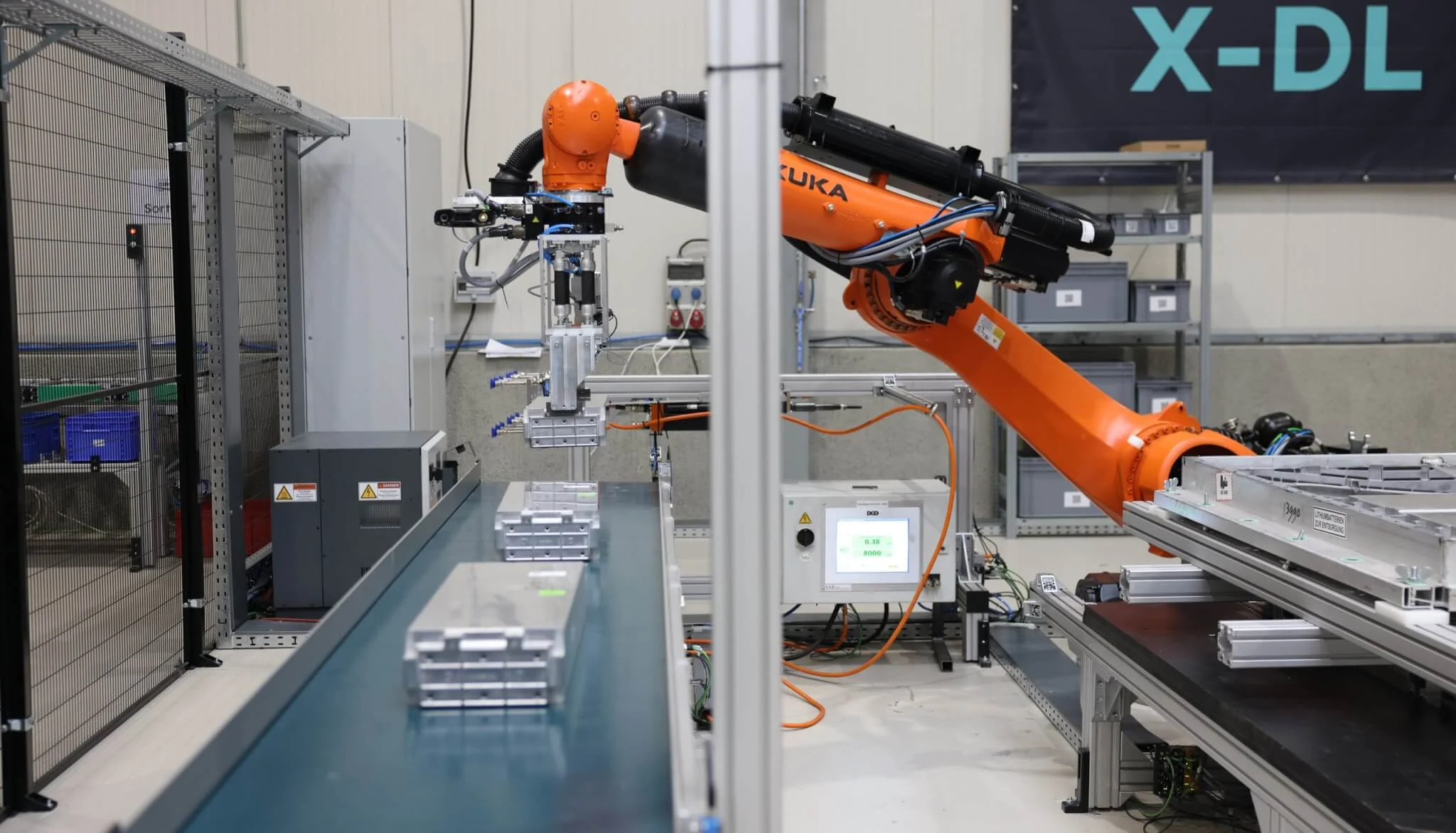

HG pointed out that R3’s system combines computer vision, AI and specialized robotic tooling to disassemble batteries, e-motors and power electronics while reducing human exposure to high-voltage risk. The company is working with Fortum Battery Recycling and automotive OEMs to deploy the technology at industrial scale, feeding recovered materials and components back into European supply chains.

The funding will support expansion of R3’s Karlsruhe “lighthouse” facility, additional deployments across Germany and France, and preparations for U.S. market entry in 2026. Former KUKA chief executive Peter Mohnen has joined the advisory board, according to HG.

Along with HG Ventures and Suma Capital, the Series A funding round participants Oetker Collection, the European Innovation Council Fund (EIC Fund), and existing shareholders including BONVENTURE, FlixFounders, and EIT Urban Mobility, alongside €6 million in European grants.

Image credit: R3 Robotics